Aggregate Supply

Rubbles is a dedicated producer and distributer of bagged and bulk aggregates from a network of quarries, depots and wharves to London and the Home Counties.

With over 60 quarrying networks, we supply both Primary Aggregates and certified and graded Recycled Aggregates. The Recycled Aggregates we provide are produced using the WRAP protocol at our aggregate production facility in Hertfordshire.

See below for the Types of Aggregate we can provide and the delivery methods available or use our Aggregate Calculator to help estimate the amount of aggregate you require for an upcoming project.

The advantages of our aggregate service are

- PRIMARY, RECYCLED AND DECORATIVE AGGREGATES AVAILABLE

- CAN BE DELIVERED LOOSE OR BY BULK BAG

- LOOSE LOADS CAN BE DELIVERED BY TIPPER LORRY (APPROX. 20t) OR GRAB LORRY (APPROX. 16t)

- BULK BAG (APPROX. 850KG) 15 BAGS PER LOAD.

- RECYCLED AGGREGATES ARE PRODUCED BY USING WRAP PROTOCOL

- DELIVERY SAME DAY / NEXT WORKING DAY

TYPES OF AGGREGATE

Aggregate can be either Primary or Recycled. Below we will be exploring the different types of aggregate we have available from each category.

Primary Aggregates

This type of aggregate is extracted directly from local quarries and are naturally derived mineral deposits. All of our Primary Aggregates are available in the standard industry gradings and specifications. Examples of Primary Aggregate we offer are detailed below, scroll and click on the headings below.

**THESE PRODUCTs are SOURCED FROM VARIOUS QUARRIES AND MAY DIFFER IN APPEARANCE AND TEXTURE DUE TO REGIONAL VARIANTS.**

MOT Type 1

MOT Type 1 is a British Standard crushed material, 0-40mm in size and is usually made from granite or limestone. It is an extremely strong and hardwearing material once it has been compacted. Due to its strength, MOT Type 1 is usually used as a sub-base creating a stable surface for roads and pathways.

USES

• Commonly used as a base for paths, driveways and roadways

• Sub-base mix of sand and aggregates

• Ideal of levelling, filling and support

10/20mm Shingle

Also known as gravel or stone, shingle is available in a range of sizes from 6mm – 40mm. Most commonly used is 4/10mm and 10/20mm shingle, for drainage purposes. Shingles are suitable for many different construction applications making it an extremely useful and versatile material.

USES

• Ideal for drainage, surface dressing and pipe bedding

• Part of a concrete mix

Sharp Sand

Also known as grit sand, river washed sand and builders sand, sharp sand is a versatile, gritty and angular material, usually used for screeding or block paving. Sharp sand is comprised of material 0-4mm in size.

USES

• Ideal for landscaping and building projects

• Use in screeding, block paving and bedding projects

• As an amendment to loosen clay soil

• To help with drainage problems

• Part of a concrete mix

Building Sand

Building Sand is a general-purpose sand, used mostly for bricklaying. It is a soft sand, usually with particles no larger than 2mm. Building sand is available as soft washed and dry screened, it comes in a variety of colours (usually red or yellow) with preferences usually based on region.

USES

• Multipurpose use in various building applications such as brickwork, ducting and bedding

• Pointing

• Paving

• Brick laying

10mm Ballast

10mm ballast is a mixture of Sharp Sand and 4/10mm shingle used in concrete production making levels and bedding.

USES

• Used in concrete production

• Bedding

20mm Ballast

A mixture of sharp sand and rough shingle 4/20mm. Not suitable for drainage due to high fines content. Widely used in industrial building but also in domestic applications such as fence posting and concrete paths.

USES

• To add cement with to make a concrete mix

• Fence posting

• Concrete paths

30/50mm Rail Ballast

This Network Rail approved rail ballast is a specialist bedding stone made from natural stone used for laying below railway sleepers.

Rail track ballast serves as a bed for rail tracks and provides drainage and strength for heavy loads carried by trains. Ballast is spread beneath the rail track. The track ballast forms the track bed that supports the rail track load and provides water drainage.

Rail ballast aggregate is typically 30-50mm aggregate. Hard and tough stone is required for rail ballast. Resists the severe attrition in a railway trackbed environment. Track ballast is typically granite as its strength delivers natural durability although other aggregate types can satisfy the requirements for trackbed ballast.

To ensure safety and performance materials are quailty tested. Our rail ballast complies to Network Rail standards for resistance to fragmentation, attrition and wear, cleanliness, durability against freeze-thaw, resistance to freeze-thawing and durability including resistance to freeze thaw and is a CE marked product.

This material can be delivered bagged or by loose loads (tipper & grab lorries).

We supply a range of aggregates to suit other projects on the railway, click here to see a list of our materials.

USES

- Commonly Rail Track Ballast is a product specially used for rail track sub bases.

Topsoil

This multi purpose topsoil is screened to 10mm making it easy to handle and ensuring it rakes out to a smooth, even tilth. Our soil is a nutrient-rich, highly fertile, organic loam, ideal for planting or for use under turf. As a general rule, each bulk bag can cover an area of 30m2 to around 1” deep. Please note this natural product is not sterilised. Certified to British Standard BS3882:2015.

USES

• Filling flower beds and large planters

Recycled Aggregates

As environmental practices demand innovative and sustainable alternatives to quarried materials, we recycle and produce materials from construction and demolition waste. All of our Aggregates are produced at our aggregate production facility in Hertfordshire, where our recycled materials are screened and washed ensuring high quality product. All of our Recycled Aggregated are WRAP approved. Examples of Recycled Aggregate we offer are detailed below, scroll and click on the headings below.

**THESE PRODUCTS ARE RECOVERED FROM VARIOUS SOURCES AND MAY DIFFER IN APPEARANCE AND TEXTURE DUE TO REGIONAL VARIANTS.**

Type 1 Crushed Concrete

Type 1 crushed concrete is screened 0-40mm in size and is produced in accordance with the specification for Highway Works 803 (SHW 803). This is a recycled and sustainable option to MOT Type 1 aggregate.

Type 1 has a lower fines percentage than scalpings and therefore a greater load bearing capability. It is the recommended material for highly trafficked areas such as highways, car parks, footpaths, driveways and hard standings.

USES

• Sub-base material for roads, drives, tracks, paths, trench fill, backfill, capping layers, oversite fills and foundations.

• Used as a general purpose hardcore.

• Backfill material

6F5

Formally known as 6F2, this recycled material is screened 75mm down to dust. 6F5 is a recycled aggregate that is made up of crushed hardcore materials including crushed concrete.

Produced from construction and demolition waste, this product offers a number of environmental benefits, making it a sustainable material.

Typically used for capping sub formations prior to laying Type 1 or Type 2 sub-base.

USES

• Ideal for embankments

• fill materials

• capping

• sub-base.

Washed Shingle

This Shingle is a by-product from demolition projects. It is a sustainable alternative for Primary 10/20mm Shingle and is often used for drainage purposes.

USES

• Ideal for drainage, surface dressing and pipe bedding

• Part of a concrete mix

Washed Sharp Sand

A sustainable and cheaper solution to Primary Sharp Sand. Sharp Sand is a versatile, gritty and angular material, usually used for screeding or block paving. Sharp sand is comprised of material 0-4mm in size.

USES

• Ideal for landscaping and building projects

• Use in screeding, block paving and bedding projects

• To help with drainage problems

• Part of a concrete mix

Reject Sand

Known as fill sand or as dug sand. Unwashed sand with clay and some small aggregate content. Reject Sand is screened to 0/5mm. Reject sand is a cost-effective fill for covering pipes and electric cables.

USES

• used for paving solutions

• for laying cable and ducting.

• Covering pipes / electric cables

• Sub-soil

Washed Ballast

A sustainable and cheap alternative to Primary Ballast. A mixture of recycled sharp sand and recycled shingle. Not suitable for drainage due to high fines content.

USES

• To add cement with to make a concrete mix

• Fence posting

• Concrete paths

Screened Topsoil

This recycled topsoil is screened 0/10mm. It is suitable for backfill, landscaping and turfing; most commonly used for land reinstatement, civil engineering and utilities maintenance.

USES

• Backfill

• Land reinstatement

• Landscaping

Tarmac Plainings

Road planings - otherwise known as tarmac planings, road scalpings or tarmac scalpings - are a by-product of road and path resurfacing, where a cold milling machine removes asphalt from the surface sub-base, ready to be recycled. Once removed and cooled, these tarmac planings are a hard-wearing and weather resistant recycled aggregate.

An inexpensive and environmentally sound way to resurface hardstandings, including car parks, footpaths, farm tracks, yards and haul roads. Can also be used as a sub-base or void filling material however has a higher content of fines compared to Type 1.

USES

• Hard-wearing and weather resident, ideal for high traffic areas.

• Use our road scalpings to resurface car parks, footpaths, farm tracks, yards and haul roads.

• Not an attractive finish so not typically suited to use in domestic gardens or driveways, except as a sub-base.

AGGREGATE DELIVERY METHODS

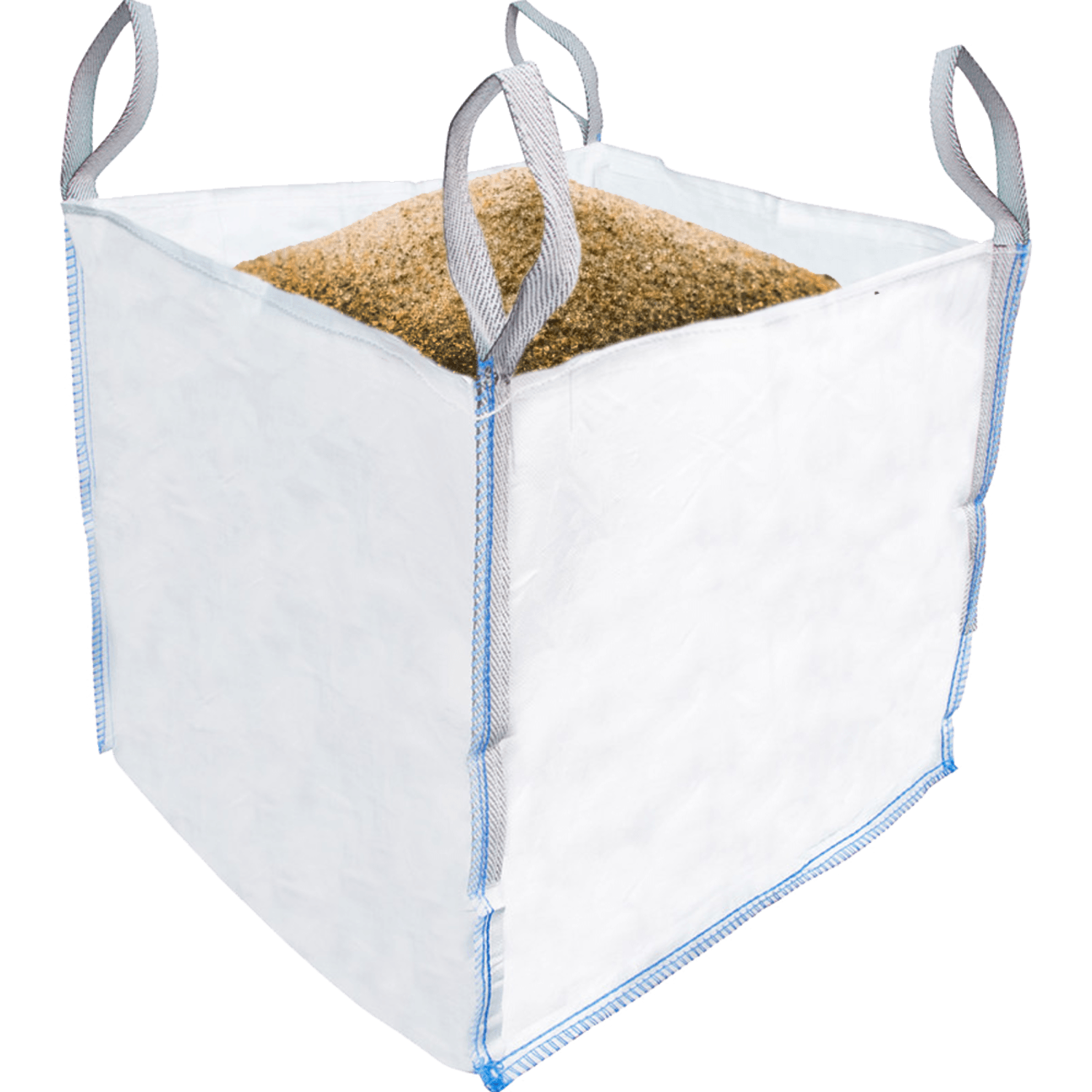

Aggregate can be delivered by either loose (in a tipper or a grab lorry) or bagged. select the image below for more information.

TIPPER DELIVERY

Button

GRAB DELIVERY

Button

BAGGED DELIVERY

Button

Delivery Methods

We can deliver aggregates by either Loose Loads or Bagged.

Loose loads can be delivered by a tipper lorry (max. 20t per load) or by a grab load (max. 15.5t per load). We have a bagged option too where we can deliver 850kg of aggregate per bag and can deliver 15 bags per load.

Please hover over the images below for more information.

-

LOOSE / BULK DELIVERY

ButtonLoose loads are available for any aggregate delivery. These can be delivered on an 8-wheeled Tipper, where the maximum carrying capacity is 20 tonne per load. Or you can opt for a Grab Lorry, where the maximum carrying capacity if 15 tonne per load. There is a minimum order of 10 tonne.

-

BAGGED DELIVERY

ButtonFor smaller quantities, we can supply any of our aggregates in Bulk Bags (850kg in weight). We can deliver up to 15 bags per load.

AGGREGATE CALCULATOR

Our Aggregates Calculator will help you determine the quantity of aggregates you need for your project. Please enter the Width, Length and Depth of the area, then click on the Calculate button.

Aggregate Calculator

Our Aggregates Calculator will help you determine the quantity of aggregates you need for your project. Please enter the Width, Length and Depth of the area, then click on the Calculate button.

Please note that calculated tonnage is approximate. We recommend that all measurements and calculations are checked by the contractor on site before placing an order.

If you would like to talk to someone about your aggregate requirements, please call our sales office on 01923 964 444.

Contact Us

We will get back to you as soon as possible.

Please try again later.

Useful links

Contact info

Email: info@rubblesskiphire.co.uk

Phone: 01923 964444

Company No.: 13050028

© 2020 Rubbles Waste Management.

All Rights Reserved.

Join the Newsletter

We will get back to you as soon as possible

Please try again later